The dazzling and almost lost art of gold beating

Gold leaf implies one of the finest manufacturing methods and the result is incomparable.

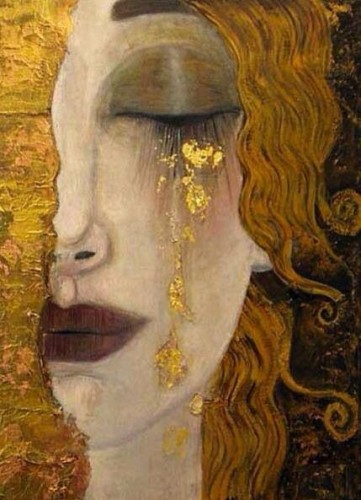

The word gold is perhaps used more in metaphor than in direct reference to the precious metal: The golden age, a heart of gold, silence is golden… With a similar dazzling metaphor, one could say that a gold thread crosses the whole tapestry of history, from the prehistoric peoples who exchanged gold grains to the stunning temples of Cleopatra, from the paintings of Klimt to our present-day finances. But with regards to its forms, gold leaf, that which has historically been used to cover buildings, sculptures, manuscripts and furniture, is the most beautiful and literally finest of all.

In ancient times this art was called lamination by fire, and perhaps its two periods of greatest splendor were, first of all, in the Middle East during the time of Cleopatra, and then in France, when Louis XVI wanted to show to the world the splendor of his country and to establish it as a world leader in the decorative arts. A sheet of gold leaf should ideally measure 0.5 microns thick, (200 times thinner than a human hair), and although to obtain it only a small amount of material is required, each piece requires the most diligent and careful artisan. In fact the profession of gold beating dates back around 4,000 years to North Africa, when laminates were applied to wood to make it look like solid gold, and continues to this day in almost all parts of the world. There is of course no gold paint that resembles the result of gold leaf; the shine it gives off is a terrestrial analogy of the sun’s purest brightness, and is where the ‘lamination by fire’ description comes from––it gives the impression of turning everything it covers into solid gold. For that reason, while there is gold in the world there will be gold leaf in its maximum artistic manifestations. But its beauty also lies in its creation.

In ancient times this art was called lamination by fire, and perhaps its two periods of greatest splendor were, first of all, in the Middle East during the time of Cleopatra, and then in France, when Louis XVI wanted to show to the world the splendor of his country and to establish it as a world leader in the decorative arts. A sheet of gold leaf should ideally measure 0.5 microns thick, (200 times thinner than a human hair), and although to obtain it only a small amount of material is required, each piece requires the most diligent and careful artisan. In fact the profession of gold beating dates back around 4,000 years to North Africa, when laminates were applied to wood to make it look like solid gold, and continues to this day in almost all parts of the world. There is of course no gold paint that resembles the result of gold leaf; the shine it gives off is a terrestrial analogy of the sun’s purest brightness, and is where the ‘lamination by fire’ description comes from––it gives the impression of turning everything it covers into solid gold. For that reason, while there is gold in the world there will be gold leaf in its maximum artistic manifestations. But its beauty also lies in its creation.

In a traditional gold leaf workshop, of which few are left, the only machinery is a tilt hammer. The gold ribbons are beaten, which measure around 11 meters in length, until their thickness is reduced to an eighth of a millimeter. Then the sheets are cut into small pieces that are placed on top of each other, separated by parchment paper. The following blows are struck by hand with a hammer weighing around 3kg, with the final blows hit home with one weighing 8kg. Finally, the sheet of just 0.5 microns thick and a package of 1,000 pieces weighs around 20g.

This handcrafted method of gold beating could be today completely replaced by machinery, but, in the words of Marino Menegazzo, one of Italy’s last gold beaters, “hand-beaten leaf is softer and more malleable, it is not metallic and stiff. Let us say that hand-made golf leaf has a soul to it.”

Related Articles

Pictorial spiritism (a woman's drawings guided by a spirit)

There are numerous examples in the history of self-taught artists which suggest an interrogation of that which we take for granted within the universe of art. Such was the case with figures like

Astounding fairytale illustrations from Japan

Fairy tales tribal stories— are more than childish tales. Such fictions, the characters of which inhabit our earliest memories, aren’t just literary works with an aesthetic and pleasant purpose. They

A cinematic poem and an ode to water: its rhythms, shapes and textures

Here lies One Whose Name was writ in Water. - John Keats Without water the equation of life, at least life as we know it, would be impossible. A growing hypothesis holds that water, including the

Watch beauty unfold through science in this "ode to a flower" (video)

The study of the microscopic is one of the richest, most aesthetic methods of understanding the world. Lucky is the scientist who, upon seeing something beautiful, is able to see all of the tiny

To invent those we love or to see them as they are? Love in two of the movies' favorite scenes

So much has been said already, of “love” that it’s difficult to add anything, much less something new. It’s possible, though, perhaps because even if you try to pass through the sieve of all our

This app allows you to find and preserve ancient typographies

Most people, even those who are far removed from the world of design, are familiar with some type of typography and its ability to transform any text, help out dyslexics or stretch an eight page paper

The secrets of the mind-body connection

For decades medical research has recognized the existence of the placebo effect — in which the assumption that a medication will help produces actual physical improvements. In addition to this, a

The sea as infinite laboratory

Much of our thinking on the shape of the world and the universe derives from the way scientists and artists have approached these topics over time. Our fascination with the mysteries of the

Sharing and collaborating - natural movements of the creative being

We might sometimes think that artistic or creative activity is, in essence, individualistic. The Genesis of Judeo-Christian tradition portrays a God whose decision to create the world is as vehement

John Malkovich becomes David Lynch (and other characters)

John Malkovich and David Lynch are, respectively, the actor and film director who’ve implicitly or explicitly addressed the issues of identity and its porous barriers through numerous projects. Now